Wood Plastic Composite Production Line

Wood Plastic Composite Production Line

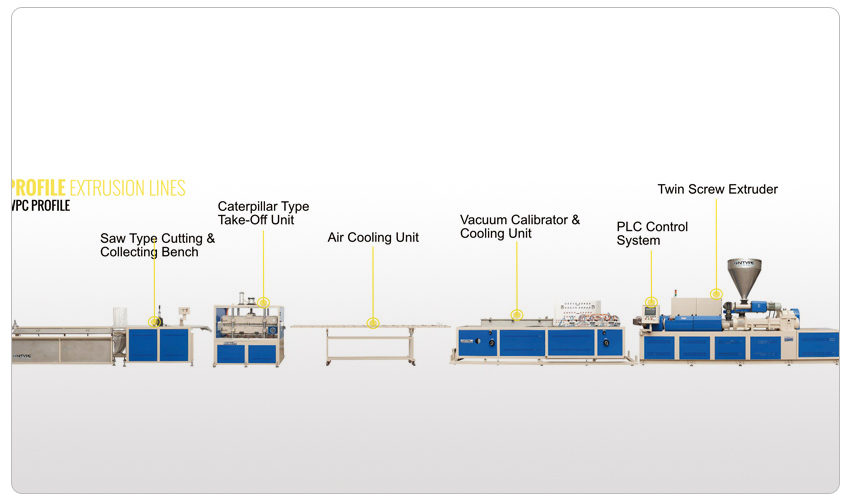

WPC profile extrusion equipment consists of twin-screw extruder, mold, stereotypes, traction, cutting machine and loading table. After the replacement of mold, wood-plastic extruder can also be used for PVC doors and windows profiles production.

Wood-plastic composite material that produced by wood-plastic equipment production line is a new type of green material. It is mainly to mix plastic raw materials (recycled PVC, PP, PE powder) and plant fiber (30-60% straw, wood flour, rice husk) together with a certain proportion, and then forming from processing. It has advantages of both wood and plastic, which is similar to the appearance of wood and has secondary processing capacity. It has the advantages of low moisture absorption, corrosion resistance and pest resistance, less maintenance. It is an excellent alternative to replace outdoor applications of wood, plastic or metal materials. Also it is mainly used in the manufacture of building panels, decorative panels, railings, pavement, steps, outdoor table siding and chairs, arbor, tree bed and etc.

| Model | SJSZ 51/105 | SJSZ 65/132 | SJSZ 80/156 | SJSZ 92/188 |

| Screw Diameter(mm) | 51mm/105mm | 65mm/132mm | 80mm/156mm | 92mm/188mm |

| Output(Kg/h) | 80-120 | 160-200 | 250-350 | 400-500 |

| Main Drive Power(kw) | 18.5 | 37 | 55 | 110 |

| Heating Area(Kw) | 3 zones, 18Kw | 4 zones, 20Kw | 5 zones, 38Kw | 6 zones, 54Kw |